We combine advanced machining strategies with comprehensive assembly services to deliver flight-ready hardware.

Complex geometries require advanced strategies. We utilize state-of-the-art multi-axis milling to deliver tight tolerances on contoured aerospace components and high-performance engine parts.

Specializing in complex blisks, impellers, and structural brackets.

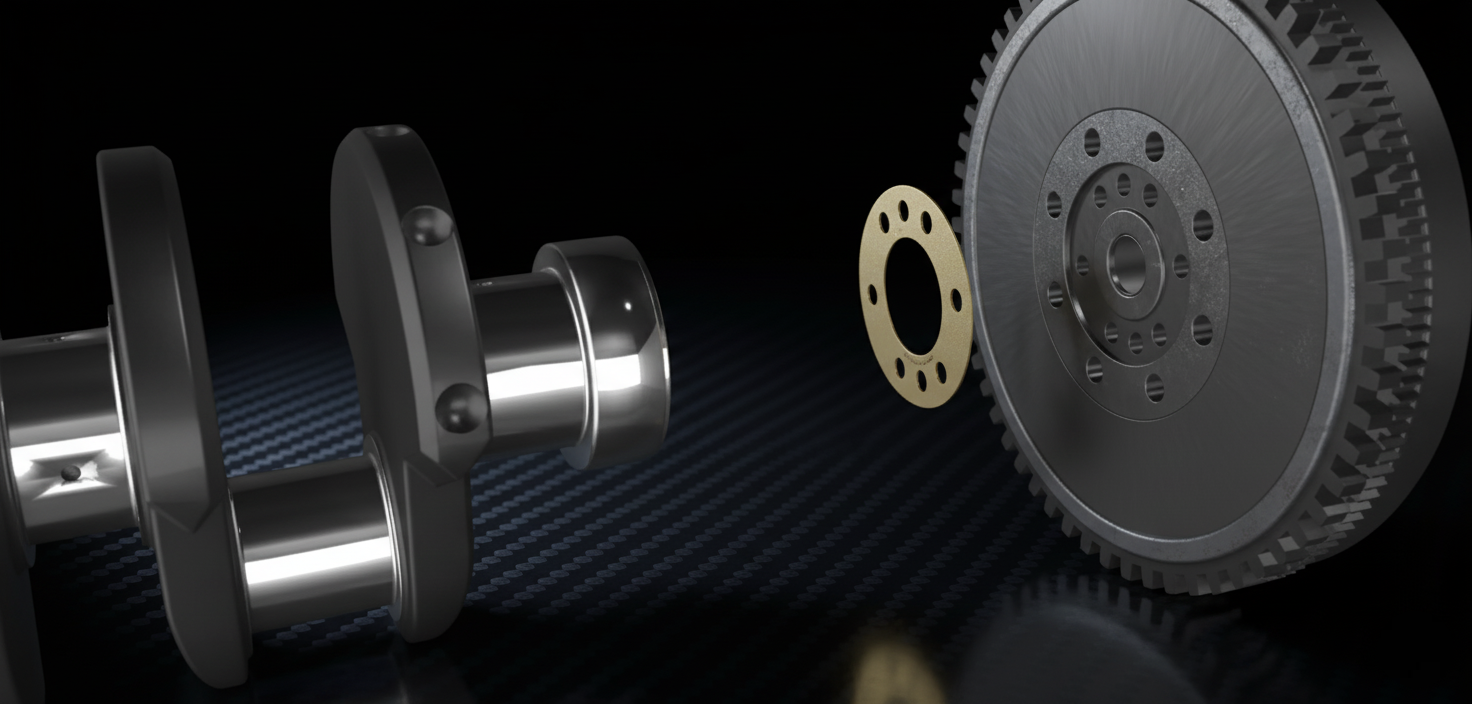

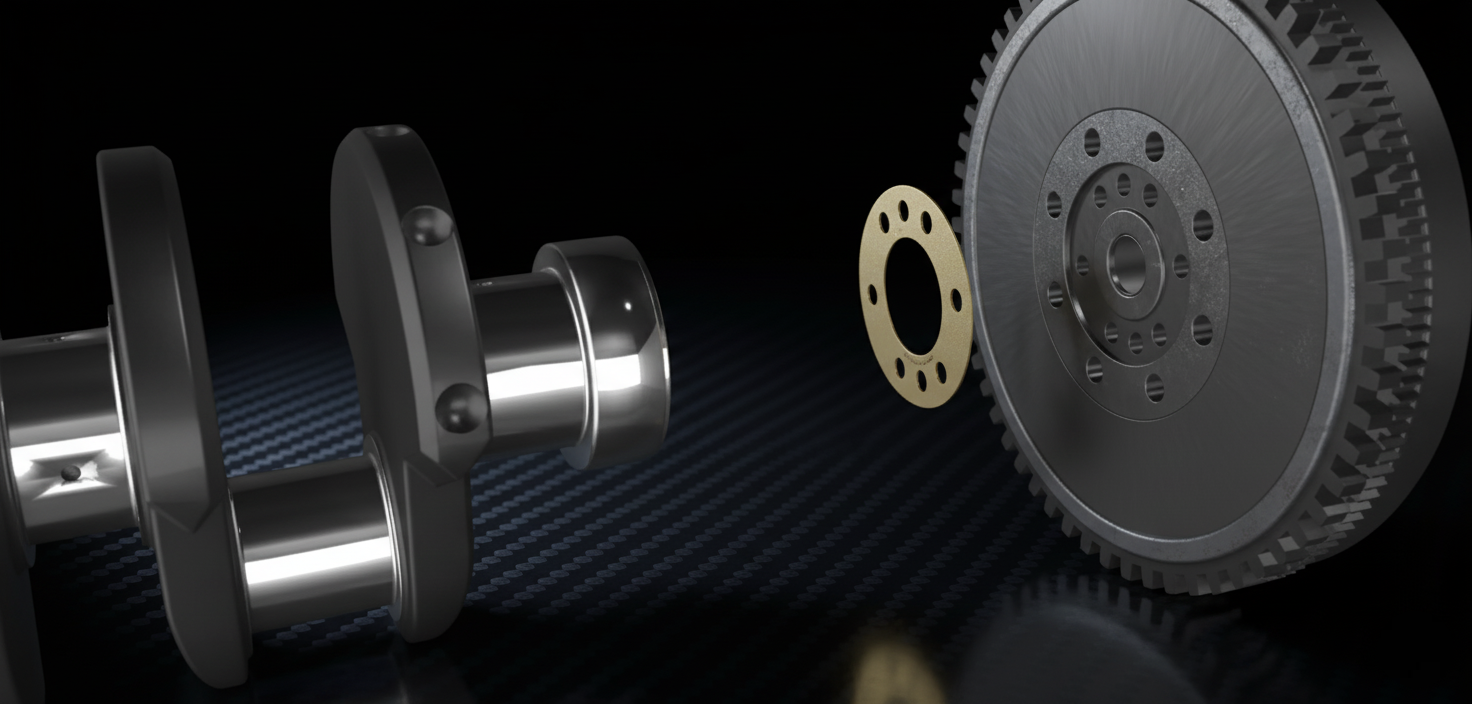

Beyond component manufacturing, we provide sub-assembly services, ensuring mechanical fit and function before the hardware leaves our floor.

Includes interference fit installation, thread inserts, and adhesive bonding.

Precision is verifiable. Our inspection lab is equipped to validate every dimension against your GD&T requirements, ensuring 100% conformity to spec.

CMM inspection with full reporting and AS9102 First Article Inspection.