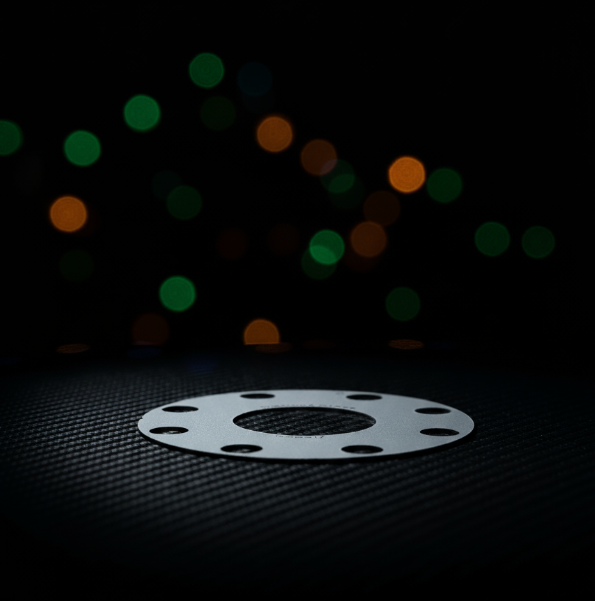

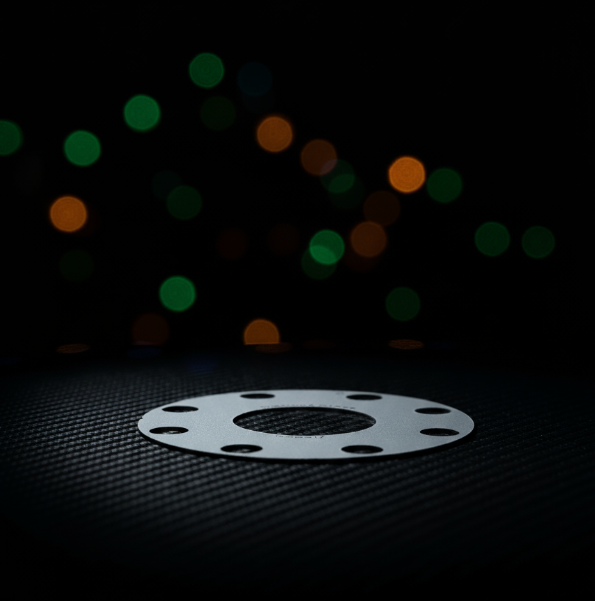

We do not just execute prints; we validate them. Our process begins with a comprehensive engineering review to ensure manufacturability, optimize tolerances, and reduce lead times without compromising structural integrity.

Whether you are launching a satellite constellation or seeking podium performance, you work directly with engineers who understand the physics of your application.

We identify manufacturing risks before the metal is cut. Our team reviews GD&T, material selection, and tolerance stacks to propose cost-saving improvements while maintaining design intent.

We are experts in machining difficult-to-cut alloys including Inconel, Titanium, Hastelloy, and Aerospace-Grade Aluminum. Our tooling strategies are optimized for these high-strength materials.

Full material certification (DFARS compliant) and AS9100-compliant processes ensure that every part we ship can be traced back to the raw billet. We provide comprehensive data packages with every shipment.

Send us your data for a secure, technical review.